What’s the difference? Well:

Hope this helps!

Please contact us with any further questions.

Just kidding. The difference between a gasket and a seal found on the factory floor is more subtle than the difference between a rubber part and a semiaquatic mammal. In fact, we would argue the real difference is much more subtle than some companies tend to tell their customers.

What is a Gasket?

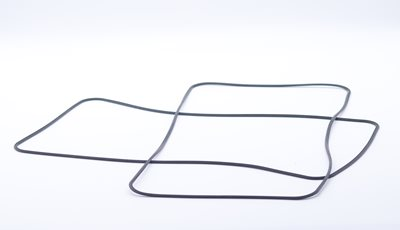

In general, a gasket is a molded shape made of a flexible material and used to seal off the space where two surfaces meet. The definition of a gasket depends almost entirely on its application.

Gaskets are widely used and can be found in almost every industrial, agricultural and manufacturing industry in America. They are very commonly employed to prevent leaks in machinery and cost little to produce.

What Industries Commonly Use Gaskets?

- Military

- Aerospace

- Chemical Processing

- Petrochemical

- Oil & Gas

- Power Generation

- Mining

What is a Seal?

Seals are molded, flexible shapes used to prevent leaks by tightly closing off the spot where two objects or surfaces meet. If this sounds similar to a gasket, that’s because they are. Both are designed and applied to prevent leaks on equipment and machinery. Like gaskets, seals are fairly cheap to produce and can be found in almost every industry across the U.S.

There are several types of named seals, including o-rings, rotary seals, mechanical seals, shaft seals, radial seals and valve stem seals. There are many, many different seals on the market, and Custom Rubber Corp. is well-versed and familiar with the majority of them.

What are Seals and Gaskets Made of?

Gaskets and seals are made with several different materials. Some are made of just one while others are a combination of two materials like metal and rubber or metal and teflon.

A few of the most common rubber polymers used to create gaskets include:

For some applications, as when a compressible gasket or seal is needed, the product can also be made of treated fibers, cork, graphite, PTFE or other compressible materials. The correct material depends on your intended application and can be determined by a skilled manufacturer.

What’s the difference between a gasket and a seal?

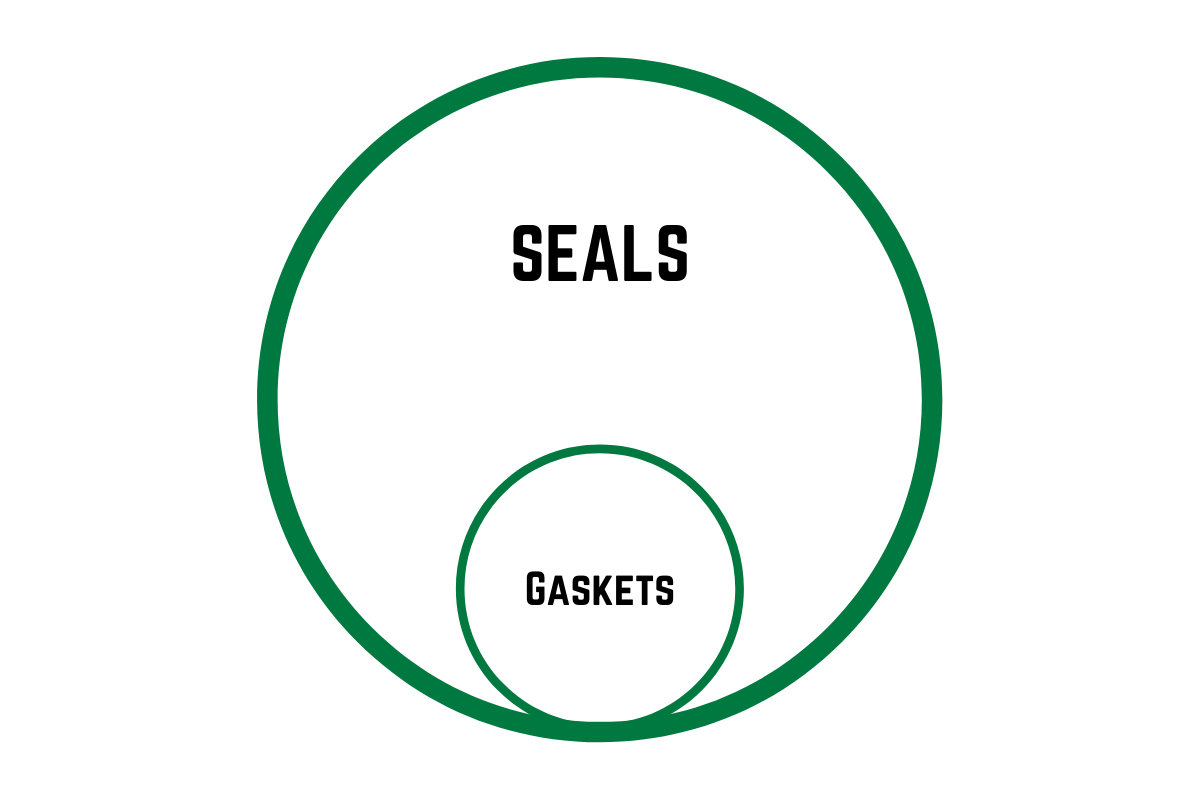

The simplest way of describing the difference between gaskets and seals is that the term “seal” is a broad category containing many different product types. A gasket is simply one of many more specific forms of a seal.

Many sources online will tell you that the big difference between gaskets and seals is that gaskets are for static machinery and seals are for more dynamic applications. But we argue that there’s no law or definition saying that seals can only be used to join moving pieces. If both are made from the same materials and used for the same applications, what’s the true difference?

In the molded rubber industry, businesses will throw around the two terms interchangeably which can cause confusion, but it’s all a matter of perspective. Businesses inside the molded rubber industry may give a slightly different answer about what a seal is compared to those in the agricultural industry.

As a rule of thumb when shopping around, the biggest difference between a gasket and a seal is simply what the manufacturer says it is. If a rubber square is listed as a gasket on one site and a seal on another, that doesn’t mean one is better than the other. It just means they both call a similar product by different names.

Custom Rubber Seals and Gaskets

At the end of the day, the best product for you depends on the materials, design and your intended application. That’s why it's best to consult a manufacturer before bulk ordering or selecting a new type of gasket or seal for your machinery.

Custom Rubber Corp. has extensive experience in

designing and producing gaskets and seals across multiple environments and applications. We are capable of solving even the most specific issues in gasket and seal performance. We have even developed special anti-fog compound formulations to ensure that gauges and dials stay readable no matter what temperature or humidity level.

Because of the critical nature of performance, our design team is available to consult on configurations and materials. Our aid with thoughtful design can also enhance end item appearance.

Whether you call it a gasket or a seal, we’re ready to help design and configure it for your specific business needs. Click here to contact Custom Rubber Corp. for more information on our gasket and seal production and design capabilities.