It is a common misconception that labor is flat-out cheaper in other manufacturing countries with a lower hourly wage. In fact, a number of manufacturers that choose to move operations overseas cite lower labor costs as a primary reason for relocation without looking at the full picture calculated by the labor cost equation.

In reality, the cost of employing qualified workers overseas is much more complex than just an hourly wage. A closer look shows a number of factors that must be taken into consideration, like rising wage costs, diminished productivity, turnover issues and market risks.

This blog is the seventh in a series detailing the costs associated with moving production overseas. Read more:

This article will explore the full labor cost equation and compare the true cost of labor in the U.S. to that of foreign nations.

How do Rising Wages Affect Overseas Business?

Rising wages are the primary reason people fail to understand the total picture of taking business overseas. This first point may come as a surprise to manufacturers under the impression that China’s labor rich market provides consistently low cost labor services that have remained stagnant for decades. Rather, China has an unusually high wage growth rate that outpaces many other manufacturing nations.

For example, examining data collected between 2000 and 2015, China’s wage rate rose 13.3%. In that same time span, U.S. wages rose at a rate of 2.8%, Brazil 4.1%, The Philippines 5.2% and South Korea 5.2%. As the U.S. is a standard-bearer for labor practices and fair wages, this wage growth in China is not just rapid, it’s beyond the norm. The climbing cost of wages in the Chinese market is consistently cited as an obstacle to success in businesses with a presence in China.

How Do Exchange Rates Affect Overseas Business Costs?

Of course, overseas labor is not paid in U.S. dollars, but rather in local currency. The exchange rates for these local currencies against the USD is unpredictable at best, further complicating the ability to predict success when moving operations overseas. Picking one example, the Chinese yuan increased in value by 18% between 2008 and 2015, then decreased 11% in just two years following. In 2019,

the yuan hit its lowest exchange rate in 11 years, and then continued to fall into 2020. Worldwide, the U.S. dollar holds different value from almost every currency on the globe, including the Australian dollar, Canadian dollar, Brazilian real, Mexican peso, Thai baht and more.

Experts can make informed guesses as to which direction the value will go year over year, but accuracy is not guaranteed. Companies are usually required to pay for the privilege of the best available exchange rate forecasts, often on a subscription basis. Also important to note is that these forecasts are written in terms of purchasing power parity (PPP) which takes into account other factors that determine how far a unit of currency will stretch in its home market, meaning results are sometimes estimated or up for interpretation.

How do Productivity Rates Change when Conducting Overseas Business?

Unit labor cost is the cost of producing one unit of output. It is used as a benchmark for measuring productivity and its relationship to wage rate. You can look at it as a measurement of the “bucks for your bang.” When productivity rises faster than wages, you’re spending low bucks for your bang. When wages rise faster than productivity, you’re spending more bucks for your bang.

In the U.S., labor unit costs have

increased steadily since 2010, meaning productivity is rising faster than wages, and manufacturers are getting a greater bang for their buck. Meanwhile, in China,

labor unit costs reached an all time high in September 2011 and then steadily decreased, reaching an all time low in April 2020. This indicates that over roughly the same time period in China, wages rose faster than productivity, increasing the buck and lowering the bang.

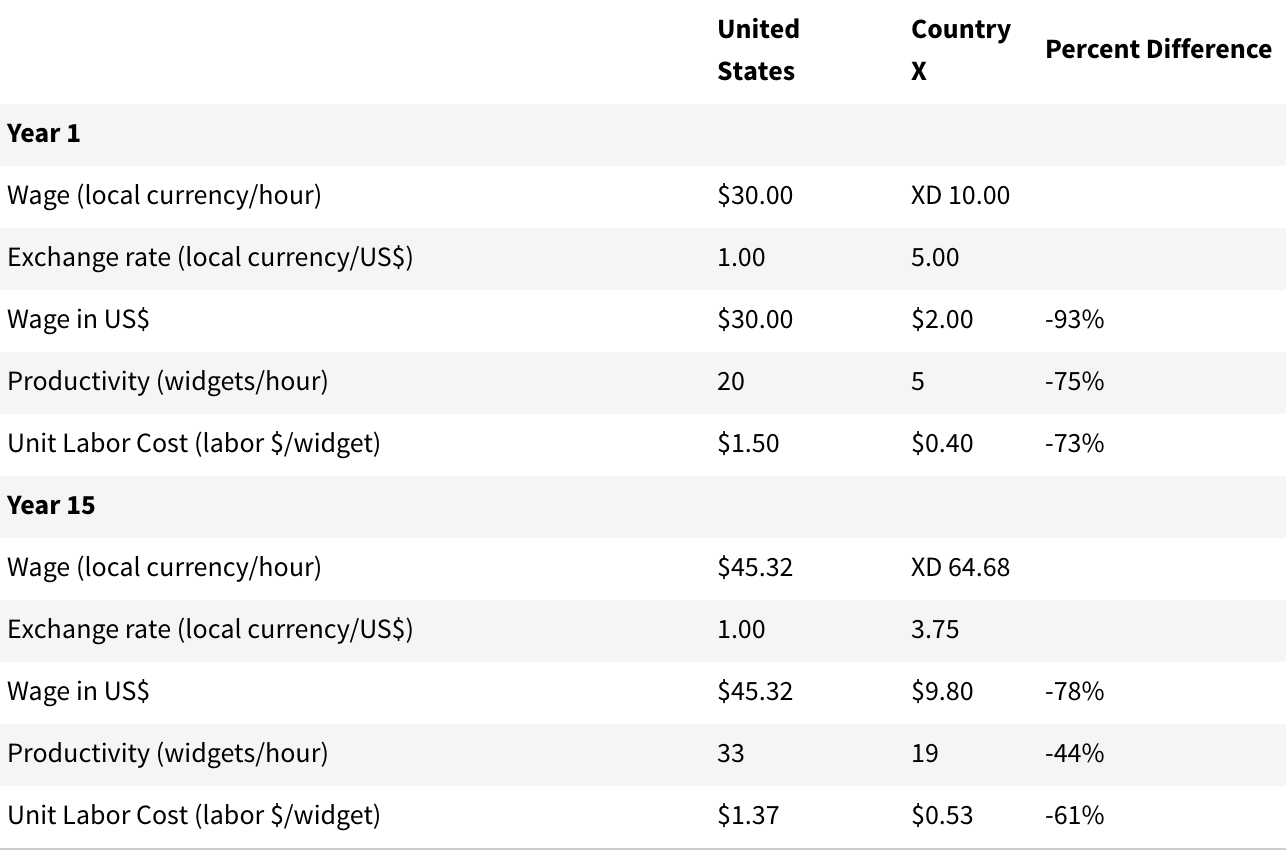

What does this mean for manufacturers looking to relocate overseas? It’s a clear example of why the labor cost equation goes well beyond hourly wages. For example, if you’re looking to move production out of the U.S. where wages are $30 per hour to one where wages are $2 per hour, you must consider productivity. If your current U.S. workers can produce 20 units per hour and the new country has lowered productivity, only producing five units per hour, then direct labor costs are $0.40 in the new country, or 73% less than in the U.S. This seems ideal on the surface, but imagine this country is China, where trends show a reduction in profits over time despite initial low costs.

When wages outpace productivity, savings diminish with time. If these two countries in our example are the U.S. and China, the unit labor cost in the U.S. would actually shrink while China’s rises. If these trends continue, unit labor cost will eventually flip flop with the U.S. becoming the cheaper option with time.

How Does Turnover Affect Overseas Business Costs?

One possible explanation for the increase in unit labor costs and rising wages in some countries is turnover, or the inability of manufacturers to attract and retain talented and skilled staff. Companies are forced to raise wages to compete in increasingly saturated markets and then invest money in training to remain competitive. Some reports show that the cost of turnover can end up around 1.5 times the annual salary of the departing worker.

The costs of turnover only increase when a company sends its operations overseas, especially if it’s the firm’s first time expanding across national borders. The culture shock of working for an American company under American managers can impact productivity for workers native to the new country. On the other hand, hiring qualified managers in a different country also presents its own set of challenges. Either way, the constant cycle of employees coming and leaving can increase when a company merges its own culture with that of another nation’s.

Other Factors in the Labor Cost Equation

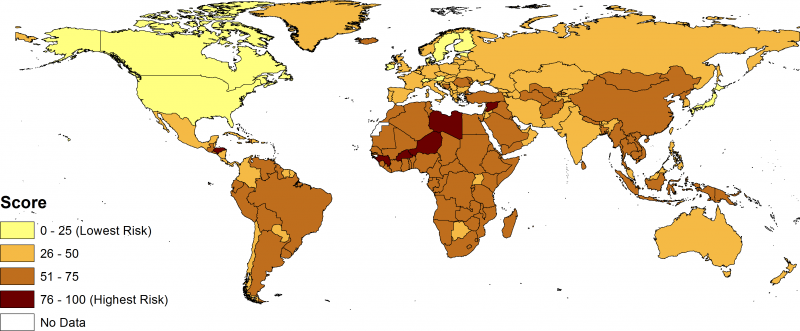

We’ve discussed so far rising wages, fluctuating productivity and turnover costs, but the full labor cost equation encompasses more than even these complex elements. To measure the full cost of labor across countries, the Economic Intelligence Unit (EIU) has developed a system to calculate “labor market risk.” Countries are rated in a scale of 0 to 100 with 100 meaning the country’s labor market presents high financial risk.

In April 2017, the lowest ranking country on this scale was Liechtenstein. Tied for second are the U.S., Switzerland and Hong Kong with 14. China came in at 57 and Mexico at 50. The map below shows an overview of labor market risk scores.

Labor Market Risk Score by Country, May 2017

Source: Economics and Statistics Administration analysis using data from the Economist Intelligence Unit

Source: Economics and Statistics Administration analysis using data from the Economist Intelligence Unit

The Full Labor Cost Equation

The idea that lower hourly wages are the only measurement to consider in terms of labor has fueled a mass exodus of American businesses moving operations overseas. But this perception, which does not consider the full labor cost equation and measurements of risk, is short-sighted at best and harmful at worst.

The true cost of labor is not stable or guaranteed and can change quickly depending on a number of factors. Wages are rising exponentially in some parts of the world, turnover can be unexpectedly high and labor can be disrupted through public policy and unrest in foreign nations.

When wise manufacturers take all costs into consideration, they usually find it to be a better investment to remain in the United States, which offers a stable labor market, high productivity and other desirable qualities for a firm’s bottom line.

If you’re looking for a domestic supplier, Custom Rubber Corp. offers services and capabilities that work with your business needs and budget. Contact Custom Rubber Corp. to learn more.