The bottom line is this: Long, complicated supply chains are expensive. Custom Rubber Corp has a strong commitment to responsiveness, from design to delivery, which means short lead times. That is why we are committed to not only delivering quality products, but also the best customer experience throughout the process.

Most companies decide to offshore because they believe it will save money, resources and time. What they may not know, however, are all of the other crucial factors that play into this process. Some of these factors help illustrate how the negatives of offshoring radically outweigh the benefits.

Is this the type of warehouse you want your products coming from?

Before delving into what can happen if your company decides to offshore, here are some necessary basic facts to get started:

- Inventory costs increase: From the moment a company places an order to when the product is actually received, foreign supply chains will typically result in increased lead time, subsequently increasing inventory costs.

- Costs add up: These longer lead times add anywhere from 20 to 30 percent to product costs. This in and of itself should outweigh the benefits of offshoring, considering there are several other costs that come into play during the process.

- Long lead times: Between the time it takes to order a product to knowing what the final market demand of that product is, cost discrepancy must be considered. It may seem appealing to offshore to a supplier who has low direct costs at first, but when taking the cost of overstocks or stockouts into consideration, oftentimes this will cost more than if a company produces the product locally.

- Cost differentials: The anticipated mismatch of costs requires a focused cost analysis to aid in making the decision for whether or not to produce locally.

- Need for more inventory: Far-flung supply chains at times have to hold inventory in case of short-term product demands. They are also needed as backup if deliveries turn up later than anticipated or damaged. Therefore, as lead time increases with offshoring, offshoring increases inventory, and increased inventory increases acquiring and carrying costs.

The conversation of offshoring doesn’t stop here. There are several other factors that companies should be made aware of so in the future they are more capable to make educated decisions.

Don’t Overlook Lead Time

The downside of offshoring suppliers is that companies have to decide how much of a product to produce before they know what the actual demand for that product will be. This, in turn, can lead to two major issues: overstocking and stockouts. Overstocking means there is more inventory than is needed, therefore higher carrying costs and money loss when those products may ultimately be sold at a marked down price. Stockouts, on the other hand, can mean losing sales and upsetting customers.

When lead times increase, so do mismatched costs. This should not be overlooked.

Hidden Inventory Mismatch Costs Can Be Big

Hidden inventory mismatch costs typically surpass the benefits of offshoring because when companies extend the supply chain to work with distant suppliers, there has to be much more variation in the demand prediction.

Your company must decide if this risk is worth it.

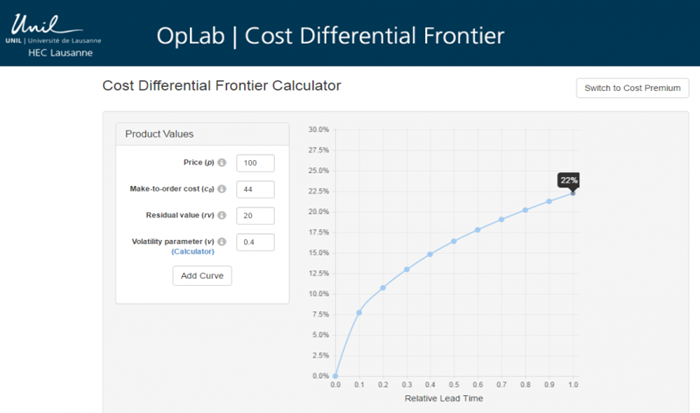

Cost Differential Frontier Calculator

This tool helps companies understand how costs increase if they decide to manufacture products far away from their customers. See the example below.

For further guidance on how to use the Cost Differential Frontier Calculator, read

this great guide from the University of Lausanne.

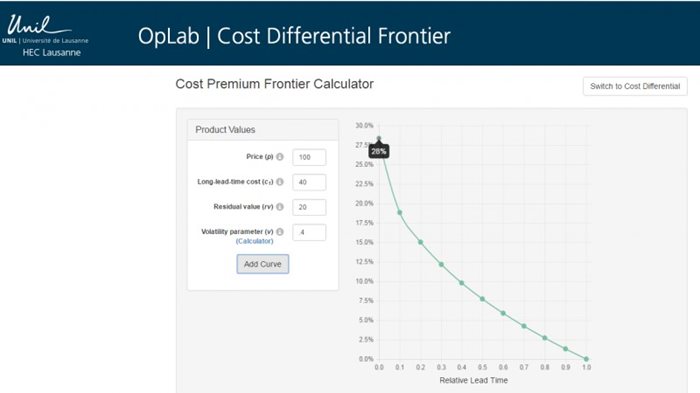

Cost Premium Frontier Calculator

This tool does the opposite of the Cost Differential Frontier by aiding companies in approximating the value of manufacturing closer to their final market. See the example below.

What is Attractive About Reshoring?

What is Attractive About Reshoring?

We’ve discussed what makes offshoring unattractive, so here are a few points that indicate why reshoring can be beneficial in regards to production.

- Unforeseen, recurrent spikes in demand

- Lower recovery value in comparison to full price

- Local suppliers can efficiently make products to order and a lead time of essentially nothing, or zero, is invaluable

Inventory Carrying Costs

As we’ve said, long lead times are costly and holding on to extra inventory adds additional costs, also known as inventory carrying costs.

Inventory carrying costs include:

- Administrative management costs

- Scrap, sorting and rework

- Obsolescence and deterioration

- Insurance

- Taxes

- Cost of capital

In addition to all of this, companies must also watch out for the carrying costs associated with the transportation of inventory. These costs can add up and should be on every company’s radar.

Supply Chain Flexibility

It’s never a bad thing if your company is the first of its competitors to offer a new product. If you source goods in close proximity to where their final market is, you decrease the amount of production time and transit cycles. It also gives leeway for adjusting any aspect of the product on a whim if needed and avoids potential waste. With longer supply chains, this flexibility diminishes because the process of having components shipped from foreign places can take a month or longer. So, if companies produce domestically, even if production costs are higher, they can win market share by simply being faster. In fact, Colliers International conducted a study in 2014 and found that 82 percent of companies take proximity to their consumers into account when making decisions about manufacturing.

In all, the cost of inventory and lead time are extremely important and need to be taken into consideration when a company decides where to manufacture. Take a look at the facts: Accenture conducted a study in 2013 and found that approximately four out of the ten surveyed manufacturers said they moved their production facilities, one third of which reported the cost of transportation was a top three reason for doing so.

The main takeaway, therefore, is this: companies that choose to offshore need to be sure that they have fully considered increased inventory costs and how having a long supply chain can hurt their business.

Contact Custom Rubber Corp to explore reshoring your products,

here.

Note: The following statistics and facts are taken from the United States of American Department of Commerce website.